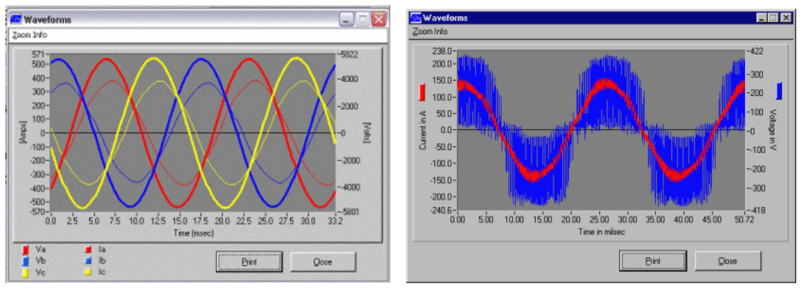

On-site condition testing is another proactive/preventative service Hibbs offers which provides data to identify potential issues prior to our customers being faced with costly downtime. Hibbs ElectroMechanical, Inc. can establish the electrical condition of motors using Baker Instruments state of the art equipment. Critical information is gathered by testing winding resistance, polarization index, insulation resistance, surge testing, high potential testing, power condition testing, along with numerous other tests. We can set up routes to establish trend data over time. Talk to Hibbs ElectroMechanical, Inc. today about planning a preventative maintenance testing program that ensures your equipment is running at peak performance. See Engineering.